Features

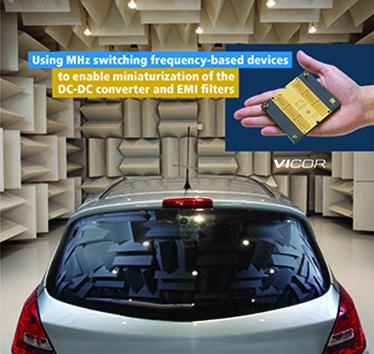

MHz switching frequency-based devices enable miniaturization of the DC-DC converter and EMI filters

Achieving EMI conducted emission compliance for automobiles with a single stage filter. By Nicola Rosano, Sr. Strategic FA/System Engineer at Vicor

More details...

AC/DC power factor correction module offers up to 1,512W

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

Power Electronics Europe Events

Warning: Trying to access array offset on value of type null in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 58

Deprecated: trim(): Passing null to parameter #1 ($string) of type string is deprecated in /home/sites/power-mag.com/public_html/includes/functions.inc.php on line 46

Warning: Trying to access array offset on value of type null in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 61

Deprecated: explode(): Passing null to parameter #2 ($string) of type string is deprecated in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 61

Warning: Trying to access array offset on value of type null in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 62

Deprecated: explode(): Passing null to parameter #2 ($string) of type string is deprecated in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 62

Warning: Undefined array key 1 in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 63

Warning: Undefined array key 2 in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 63

Fatal error: Uncaught TypeError: mktime(): Argument #6 ($year) must be of type ?int, string given in /home/sites/power-mag.com/public_html/event.detail.inc.php:63 Stack trace: #0 /home/sites/power-mag.com/public_html/event.detail.inc.php(63): mktime(0, 0, 0, NULL, NULL, '') #1 /home/sites/power-mag.com/public_html/event.detail.php(5): include('/home/sites/pow...') #2 {main} thrown in /home/sites/power-mag.com/public_html/event.detail.inc.php on line 63