Features

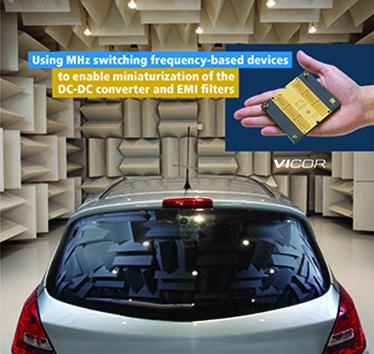

MHz switching frequency-based devices enable miniaturization of the DC-DC converter and EMI filters

Achieving EMI conducted emission compliance for automobiles with a single stage filter. By Nicola Rosano, Sr. Strategic FA/System Engineer at Vicor

More details...

AC/DC power factor correction module offers up to 1,512W

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

Power Electronics Europe News

TE Connectivity Introduces Latest SPE M12 Hybrid Connectors, Setting a Milestone in Industrial Communication

TE Connectivity (TE), a leader in connectors and sensors, has announced it is presenting a Single Pair Ethernet (SPE) hybrid connector in M12 format.

The company says this development helps enable users to connect systems and machines within factory floor networks. As an SPE pioneer and key contributor, TE says it supports industrial customers in leveraging the latest SPE technology – driving faster and broader market adoption.

TE’s latest SPE M12 hybrid connectors, which comply with the IEC 63171-7 standard, support the integration of power-demanding field devices into the network and transmit large amounts of data in real time to the control system or the cloud.

The compact SPE M12 hybrid connectors support the transmission of high-speed data and unprecedented current levels over a single cable. This makes this connection technology excellent for robotics systems and drives, as well as for future IIoT applications in automation technology. In particular, the trend toward miniaturisation is supported, as devices (eg. cobots, grippers, sensors and vision systems) can feature higher performance within the same M12 form factor and without increasing space requirements.

Latest SPE M12 interface delivers more data and power supporting latest trends

Existing hybrid connectors that meet IEC 61076-2-113 standard, deliver only 2 x 6 A and 100 Mbit/s, restricting high-power devices and fast data exchange. TE's latest SPE M12 hybrid is an industrial connector that combines data and power transmission in a single interface. It supports high-speed data transmission at up to 1 Gbit/s, helps enabling real-time communication at data rates 10 times higher than in previous industrial applications. The 2 x8 A power supply supports the operation of power-demanding components up to approximately 1 kW.

TE has developed the connector for harsh environments and designed it to be highly robust with an IP67 protection rating. It supports interoperability between devices and manufacturers thanks to its standardised mating face. Its integrated design simplifies cabling, prevents cable clutter, and lowers installation costs.

Communication takes place via advanced Ethernet protocols, reducing the need for gateways and fieldbus couplers. Developers and designers of plants and systems can incorporate the standardised and future-proof SPE M12 interfaces into their designs, increasing planning reliability and reducing development costs.

Overcoming former M12 connector limitations

Conventional M12 connectors have limitations in terms of power and data transmission. This makes it difficult to meet the requirements of Industry 4.0. The existing barriers are to be overcome by the IEC 63171-7 edition 2 and corresponding products, which extend adopted SPE standards to the M12 hybrid format.

TE says its latest SPE M12 hybrid connector consistently follows this approach. It supports trends such as decentralisation, miniaturisation, and digitalisation in industrial environments and provides for a high degree of interoperability between devices even from different manufacturers.

From engineer’s vision to technological reality

As a founding member of the SPE Industrial Partner Network and being one of the leaders in user organisations and standardisation bodies, TE says it is driving the extension of the new IEC 63171-7 standard for an extensive industrial SPE ecosystem. The latest version (Edition 2) of this standard marks a significant step forward in the development of industrial connectivity and the acceleration of Industry 4.0 adoption.

Manuel Rüter, Senior Principal of Technology, Standardisation and Consortia at TE, says: “By aligning with the global Ethernet infrastructure and helping to enable interoperability across devices and systems, the new standard is expected to accelerate market adoption of SPE technologies, reduce complexity, supports end-to-end Ethernet, and helps enhance sustainability by reducing copper cables.”

View PDF

The company says this development helps enable users to connect systems and machines within factory floor networks. As an SPE pioneer and key contributor, TE says it supports industrial customers in leveraging the latest SPE technology – driving faster and broader market adoption.

TE’s latest SPE M12 hybrid connectors, which comply with the IEC 63171-7 standard, support the integration of power-demanding field devices into the network and transmit large amounts of data in real time to the control system or the cloud.

The compact SPE M12 hybrid connectors support the transmission of high-speed data and unprecedented current levels over a single cable. This makes this connection technology excellent for robotics systems and drives, as well as for future IIoT applications in automation technology. In particular, the trend toward miniaturisation is supported, as devices (eg. cobots, grippers, sensors and vision systems) can feature higher performance within the same M12 form factor and without increasing space requirements.

Latest SPE M12 interface delivers more data and power supporting latest trends

Existing hybrid connectors that meet IEC 61076-2-113 standard, deliver only 2 x 6 A and 100 Mbit/s, restricting high-power devices and fast data exchange. TE's latest SPE M12 hybrid is an industrial connector that combines data and power transmission in a single interface. It supports high-speed data transmission at up to 1 Gbit/s, helps enabling real-time communication at data rates 10 times higher than in previous industrial applications. The 2 x8 A power supply supports the operation of power-demanding components up to approximately 1 kW.

TE has developed the connector for harsh environments and designed it to be highly robust with an IP67 protection rating. It supports interoperability between devices and manufacturers thanks to its standardised mating face. Its integrated design simplifies cabling, prevents cable clutter, and lowers installation costs.

Communication takes place via advanced Ethernet protocols, reducing the need for gateways and fieldbus couplers. Developers and designers of plants and systems can incorporate the standardised and future-proof SPE M12 interfaces into their designs, increasing planning reliability and reducing development costs.

Overcoming former M12 connector limitations

Conventional M12 connectors have limitations in terms of power and data transmission. This makes it difficult to meet the requirements of Industry 4.0. The existing barriers are to be overcome by the IEC 63171-7 edition 2 and corresponding products, which extend adopted SPE standards to the M12 hybrid format.

TE says its latest SPE M12 hybrid connector consistently follows this approach. It supports trends such as decentralisation, miniaturisation, and digitalisation in industrial environments and provides for a high degree of interoperability between devices even from different manufacturers.

From engineer’s vision to technological reality

As a founding member of the SPE Industrial Partner Network and being one of the leaders in user organisations and standardisation bodies, TE says it is driving the extension of the new IEC 63171-7 standard for an extensive industrial SPE ecosystem. The latest version (Edition 2) of this standard marks a significant step forward in the development of industrial connectivity and the acceleration of Industry 4.0 adoption.

Manuel Rüter, Senior Principal of Technology, Standardisation and Consortia at TE, says: “By aligning with the global Ethernet infrastructure and helping to enable interoperability across devices and systems, the new standard is expected to accelerate market adoption of SPE technologies, reduce complexity, supports end-to-end Ethernet, and helps enhance sustainability by reducing copper cables.”

View PDF

| Home / News / Features / Events / Media Data / Issue Archive / Magazine Subscription / Contact Us

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media