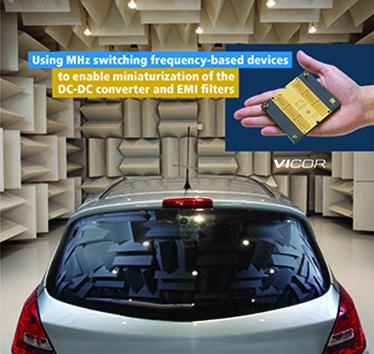

MHz switching frequency-based devices enable miniaturization of the DC-DC converter and EMI filters

Achieving EMI conducted emission compliance for automobiles with a single stage filter. By Nicola Rosano, Sr. Strategic FA/System Engineer at Vicor

More details...

A full brick package developed by TDK-Lambda, the PF1500B-360, is for high voltage distributed power architectures

More details...

The 4.0A AOZ2231CQI-01 and the 8.0A AOZ2233CQI-02 support dynamic voltage scaling (DVS)/voltage margining. They are the first two members of the regulator family with I2C control.

The 4.0A AOZ2231CQI-01 and the 8.0A AOZ2233CQI-02 support dynamic voltage scaling (DVS)/voltage margining. They are the first two members of the regulator family with I2C control.

They provide a compact, efficient power converter solution for next-generation chipsets and FPGAs used in high-end TVs, set-top boxes, data storage systems, servers and other embedded systems, says the company.

Next-generation microprocessors and SoCs often use DVS to reduce power dissipation and improve system performance. Implementing DVS in a DC/DC converter often requires several external components. According to the company, these two devices make the design of such converters simple by allowing the system designer to control the output voltage from 0.6 to 1.79V using an I2C interface with 9.375mV steps.

The regulators combine the company’s MOSFET technology with advanced packaging technology for a compact footprint. The MOSFETs enable high efficiency over the entire load range, and light load efficiency gets a further boost with an optional pulse frequency mode (PFM). Both are available in footprint-compatible QFN 4.0 x 4.0mm package for an upgrade path as power requirements increase.

The devices operate over a wide input voltage range of 6.5 to 28V and have a built-in 5.3V regulator making single supply operation possible. The proprietary COT architecture provides fast load transient response performance and allows stable and low voltage ripple operation with small ceramic capacitors. According to the company, competing solutions require several external components when using all ceramic capacitors and need to generate a larger output ripple voltage to stabilise the circuit. The input feed forward feature provides a constant switching frequency over the entire input voltage range, which further alleviates noise concerns for designers.

Both devices are immediately available in production quantities with a lead-time of 12 weeks.

View PDF

| Privacy Policy | Site Map | © Copyright DFA Media

| Web design by Immersive Media